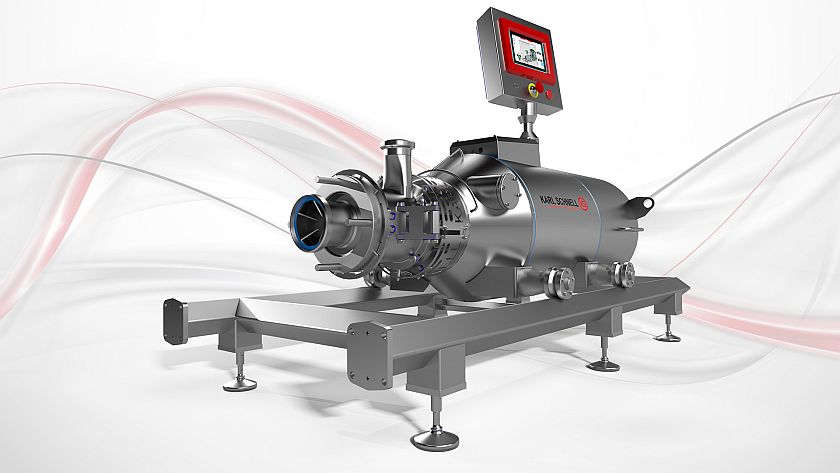

As a leading machine manufacturer, KARL SCHNELL GmbH & Co. KG goes far beyond the provision of hardware, software and service. With a clear self-image as a “solution provider”, the company presents its latest Emulsifier FL175 DSE, which offers significant added value in the food industry thanks to its sophisticated hygienic design. The concept includes the consistent implementation of the requirements for a hygienic design in accordance with the latest food industry guidelines. A highly hygienic universal drive unit, the innovative emulsifying unit and the intelligent Smart Control System are the key components. The universal drive unit has a maximum drive power of 150 kW and is characterized by a wide speed range between 50 and 4500 rpm with constant torque. Completely made of stainless steel and certified to protection class IP69, it guarantees the highest hygiene standards. Low-noise, energy-efficient continuous operation is ensured by the hygienic water cooling and the powerful servo motor. The motor shaft, which can be axially adjusted by ±5 mm, enables application-oriented cutting set adjustment without loss of power over the entire adjustment range.

When it comes to the emulsifying unit, KARL SCHNELL can rely on the world’s largest range of cutting systems. The intelligent combination of several cutting principles in one machine enables the production of homogeneous, extremely fine products in one operation, with minimal wear and maximum process reliability. This is particularly important in modern production facilities and offers the greatest possible efficiency with minimal product losses, especially when cleaning after a product change. The optional product feed via a KS feed hopper with integrated screw allows precise temperature control, even with highly viscous raw materials, and also offers a further increase in production speed in the process. The KS Emulsifier FL175 DSE sets new standards in terms of speed and fineness in the production of food.

When it comes to the emulsifying unit, KARL SCHNELL can rely on the world’s largest range of cutting systems. The intelligent combination of several cutting principles in one machine enables the production of homogeneous, extremely fine products in one operation, with minimal wear and maximum process reliability. This is particularly important in modern production facilities and offers the greatest possible efficiency with minimal product losses, especially when cleaning after a product change. The optional product feed via a KS feed hopper with integrated screw allows precise temperature control, even with highly viscous raw materials, and also offers a further increase in production speed in the process. The KS Emulsifier FL175 DSE sets new standards in terms of speed and fineness in the production of food.

The control system includes temperature and system monitoring. This ensures consistent product quality throughout the entire process. Access is via personalized RFID login for different user levels. KS Smart Control enables the setting of definable shearing positions and automatic temperature-dependent expansion correction. Control takes place directly on the emulsifier via PLC and can be seamlessly integrated into a complete system control. The hygienic design of the control cabinets is standard for KS machines, ensuring trouble-free production even in wet rooms. This concept is used in almost all areas of the food industry, with a focus on highly hygienically sensitive areas such as baby food and delicatessen production.

Visit KS live at Anuga Foodtec in Cologne.