IDM ¦ Packaging

Stretch blow molder with high energy

savings gentle on the environment

With the integration of the stretch blow molder the aseptic block

gains a number of further plus points. One of these is that the

heating system in the new Blomax generation consumes up to

40% less energy compared to most standard heating systems

thanks to its optimized near infrared heating concept and new

Double Gate technology. This is made possible by the near infrared

heater centrally installed in the closed reflector tunnel. In the heater

the preforms pass the centrally arranged heating units to both

the left and right. The preforms are spaced just around 18 millimeters

apart instead of the previous approximately 37 millimeters.

The Dortmund systems supplier has thus been able to considerably

reduce the number of heater boxes used. The air management

system for heater box ventilation has also been optimized. “The

fan can be set separately for the neck, reflector and lamps. This

means that the machine only cools the areas which actually need

cooling,” explains Redeker.

Effective sterilization with the KHS system

When further developing its linear aseptic filler KHS also focused

on increased efficiency. The filling machine for sensitive products

is available in both a standard aseptic and ESL version. In the KHS

process sterilization takes place in several stages. First, the machine

disinfects the neck and bottle interior. Here, the inside of the container

is sprayed twice with a hydrogen peroxide aerosol (H2O2) at a

speed of up to 80 kilometers an hour. “This ensures that every part

of the bottle is sprayed and sterilized; we even achieve this with

individual designs and critical shapes,” Redeker states. Secondly,

two aerosol reaction cycles are initiated. The process ends with a

four-stage drying process which uses sterile hot air.

Gentle filling ensures product protection

In order to ensure the quality of the products, it is essential that the

aseptic zone is absolutely clean. KHS ensures this by gentle noncontact

filling, among other things, performed in two stages. This

prevents any excessive beverage foaming.

After filling the bottle is conveyed to the capping unit. Here,

the closure is sterilized in the same manner as the bottle in the fill-

The new linear InnoPET BloFill ABF aseptic block from KHS is

designed to fill milk, mixed milk beverages, juice, smoothies

and iced tea into PET bottles holding between 250 milliliters

and two liters (Photo: KHS GmbH)

18 · February 2020 ¦ international-dairy.com

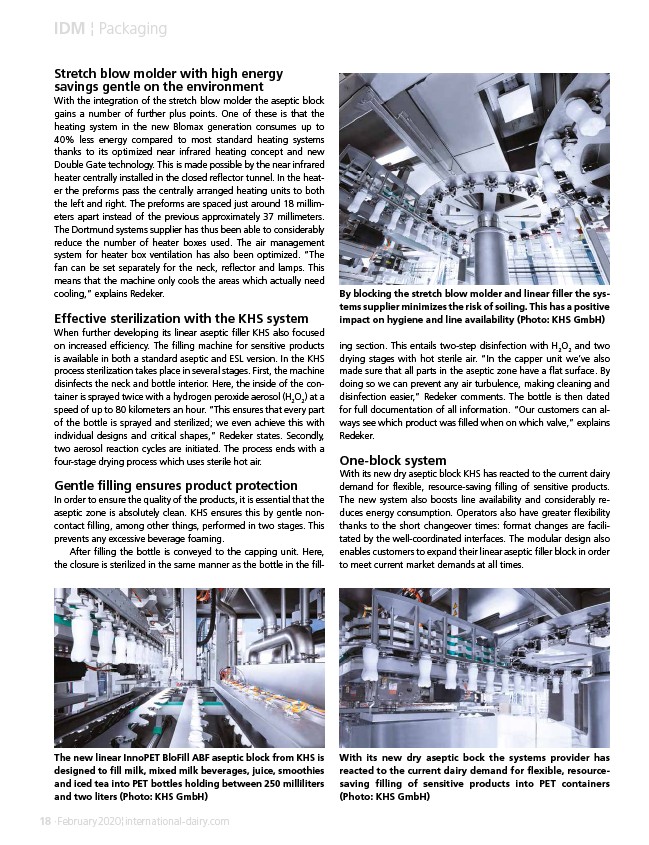

By blocking the stretch blow molder and linear filler the systems

supplier minimizes the risk of soiling. This has a positive

impact on hygiene and line availability (Photo: KHS GmbH)

ing section. This entails two-step disinfection with H2O2 and two

drying stages with hot sterile air. “In the capper unit we’ve also

made sure that all parts in the aseptic zone have a flat surface. By

doing so we can prevent any air turbulence, making cleaning and

disinfection easier,” Redeker comments. The bottle is then dated

for full documentation of all information. “Our customers can always

see which product was filled when on which valve,” explains

Redeker.

One-block system

With its new dry aseptic block KHS has reacted to the current dairy

demand for flexible, resource-saving filling of sensitive products.

The new system also boosts line availability and considerably reduces

energy consumption. Operators also have greater flexibility

thanks to the short changeover times: format changes are facilitated

by the well-coordinated interfaces. The modular design also

enables customers to expand their linear aseptic filler block in order

to meet current market demands at all times.

With its new dry aseptic bock the systems provider has

reacted to the current dairy demand for flexible, resourcesaving

filling of sensitive products into PET containers

(Photo: KHS GmbH)