Premium fruit and vegetable ingredient supplier SVZ has today announced a strategic investment for its Belgian processing plant in Rijkevorsel. The latest in a series of global growth and sustainability-focused investments, SVZ seeks to expand the facility’s capacity to meet rising consumer demand for fruit and vegetable ingredients – while also boosting its sustainability credentials.

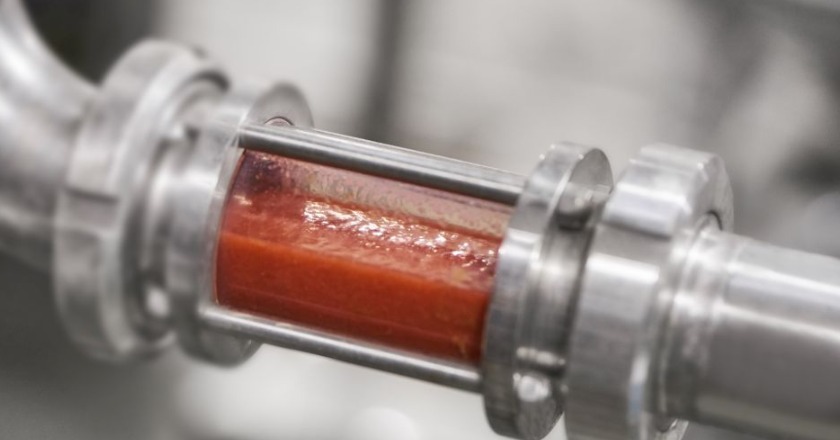

Demand for naturally healthy, nutritious ingredients is growing as consumers become more aware of the impact what they consume has on their wellbeing. To fulfil this need, SVZ is investing in the capacity and processing technology required to process larger quantities of fruit and vegetable ingredients on-site without compromising on quality. A new pasteuriser in the plant, for example, will allow its Belgium facility to boost its puree production significantly.

This investment follows similar expansions across SVZ’s global processing plants, as the business meets this heightened demand for fruit and vegetable ingredients. In Poland, for example, the Tomaszów facility’s concentrate line has been bolstered, while SVZ’s US-based plant has not only boosted its puree line but is also investing in new automation technology to streamline the production process even further.

Sustainability first

SVZ’s investment in the Rijkevorsel plant also supports the business’ sustainability efforts – and progress towards its 100% sustainable sourcing goal. The Belgium facility has seen a massive reduction in CO2 emissions over the last two years – and this new effort will aim to build on this by further decreasing heat consumption and exploring new ways of reusing expended energy within the facility. Indeed, the new pasteuriser will reduce emissions by 19% – a crucial step in SVZ’s journey to low carbon production.

This new investment also contributes to SVZ’s broader mission of boosting the sustainability credentials of all global processing sites. SVZ’s Spain-based plant in Almonte, for example, has been recently fitted with solar panels, and a new cold storage facility has also been constructed to reduce reliance on third party-storage and transportation. Meanwhile, SVZ’s US processing plant has focused recent investment on water treatment, so water can be cleaned and reused.