Discover iXAPACK GLOBAL’s manufacturing process, 100% French-made and based in a single production site, in the West of France. A single contact point at disposal for 3 machines’ creation phases for the Food and Cosmetic industries: Design, Manufacturing and Monitoring, handled entirely in-house.

Phase 1: Study and Design

Creation of the preliminary project within iXAPACK GLOBAL Commercial Project Office for a technical design, to precisely define the equipment to be put in place before its validation, according to given specifications. Then, the various design offices of the company take over. Mechanism, electricity, IT, and automation, no aspect of the machine’s design is left to chance.

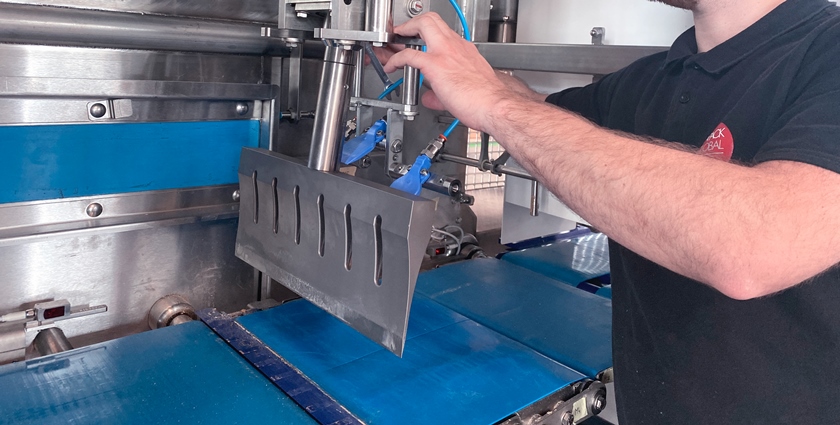

Phase 2: Manufacturing

After the 3D design of the machine and all its elements, the assembly is transmitted to the manufacturing departments: Machining, Turning Milling, Robot Welding, Cabling… Each element that makes up the equipment (parts, cables, chassis, connectors…) is manufactured, machined, folded, welded in iXAPACK’s workshops, for a made-to-measure fabrication adapted to client’s request. Each machine is then pre-assembled and assembled (still in-house) for the test phases. After few final adjustments, the equipment is ready to be delivered!

Phase 3: Installation and follow-up

For a ‘turnkey’ installation of the line, iXAPACK GLOBAL’s team comes to client’s workshops to commission, adjust the equipment and train operators. Constant monitoring is also ensured with the after-sales service, always ready to intervene to deliver spare-parts that iXAPACK keeps in stock, ensure the maintenance of machines and support the clients in the development of their productions. For more visit ixapack.com