IDM ¦

dle product message changeover, and

work in unison with external vision systems

for message validation.

Late-stage customisation

Bringing all elements of production

together under one roof is the ultimate

goal of smart manufacturing.

Domino’s options for late-stage customisation

offer increased control

over product identification and coding,

allowing manufacturers to easily

adapt to smaller batch sizes, tighter

lead times, and changing packaging

concepts. domino-printing.com

Linx

Ink for retort applications

Linx Printing Technologies has introduced

an ink (Linx Black retort ink

1077) specially formulated to resist

moisture, colour change and transference.

It is ideal for consistent coding

through pouch and can retort applications

where the contents are cooked in

the packaging after they are coded.

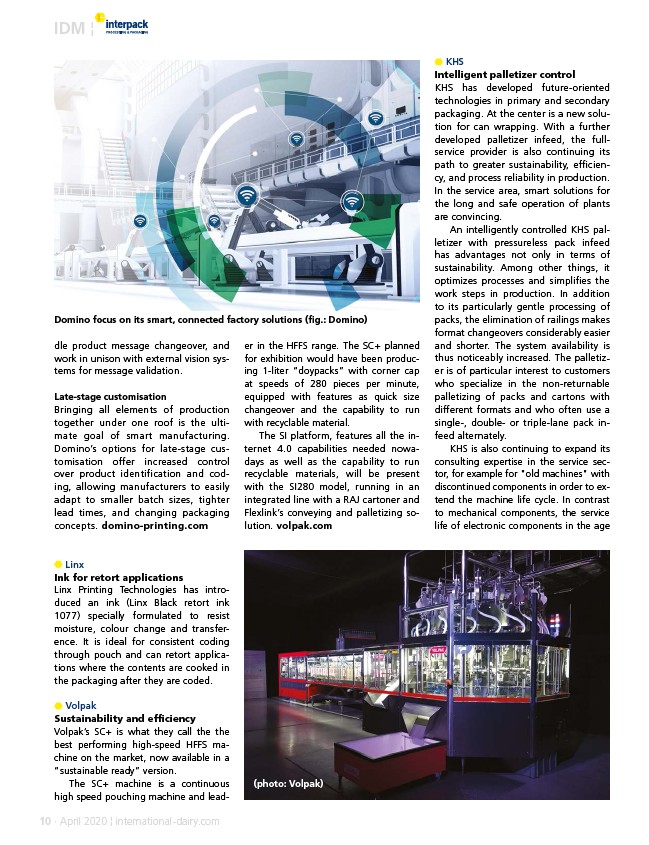

Volpak

Sustainability and efficiency

Volpak’s SC+ is what they call the the

best performing high-speed HFFS machine

on the market, now available in a

“sustainable ready” version.

The SC+ machine is a continuous

high speed pouching machine and leader

10 · April 2020 ¦ international-dairy.com

in the HFFS range. The SC+ planned

for exhibition would have been producing

1-liter “doypacks” with corner cap

at speeds of 280 pieces per minute,

equipped with features as quick size

changeover and the capability to run

with recyclable material.

The SI platform, features all the internet

4.0 capabilities needed nowadays

as well as the capability to run

recyclable materials, will be present

with the SI280 model, running in an

integrated line with a RAJ cartoner and

Flexlink’s conveying and palletizing solution.

volpak.com

KHS

Intelligent palletizer control

KHS has developed future-oriented

technologies in primary and secondary

packaging. At the center is a new solution

for can wrapping. With a further

developed palletizer infeed, the fullservice

provider is also continuing its

path to greater sustainability, efficiency,

and process reliability in production.

In the service area, smart solutions for

the long and safe operation of plants

are convincing.

An intelligently controlled KHS palletizer

with pressureless pack infeed

has advantages not only in terms of

sustainability. Among other things, it

optimizes processes and simplifies the

work steps in production. In addition

to its particularly gentle processing of

packs, the elimination of railings makes

format changeovers considerably easier

and shorter. The system availability is

thus noticeably increased. The palletizer

is of particular interest to customers

who specialize in the non-returnable

palletizing of packs and cartons with

different formats and who often use a

single-, double- or triple-lane pack infeed

alternately.

KHS is also continuing to expand its

consulting expertise in the service sector,

for example for "old machines" with

discontinued components in order to extend

the machine life cycle. In contrast

to mechanical components, the service

life of electronic components in the age

Domino focus on its smart, connected factory solutions (fig.: Domino)

(photo: Volpak)