IDM ¦ Packaging

A closed cycle

Complete-line competence from Krones

Can plastic packages be sustainable?

Yes, if they are resourceeconomically

produced and

kept in a closed cycle. Krones

offers a solution for every step

involved in the process. From material-minimised

packaging design and energy-economical

container production all the way

through to the recycling of used plastics.

The aim is to achieve a sustainable beverage

factory with a closed PET cycle – a vision

that’s now within our reach. Because

all the building blocks needed are already

included in the Krones Group’s portfolio.

For producing the preforms, every tenth

of a second in cycle time and every tenth of

a gram in weight are vital. There are plenty

of potential savings. In order to use them,

there are two preconditions: firstly, comprehensive

knowledge of the properties and

behaviour of the various preform materials;

and secondly an in-depth understanding of

the production processes involved – both

during injection-moulding of the preforms

and also when identifying the salient parameters

for the stretch blow-moulding

function. Based on its innovative hot-channel

technology developed in-house, the

Krones subsidiary MHT offers a sophisticated

high-performance injection-moulding

tool that even with a flakes content of

over 70 per cent rPET achieves superlative

results. In addition, it excels in term of particularly

homogeneous temperature control

of the melt, and natural balancing.

For the further path of the preform to a

saleable product, Krones’ portfolio includes

an entire bandwidth of technical solutions.

With the Contiform stretch blow-moulding

machines, preforms with a recyclate

content of 100 per cent can be handled

without any problems at very low energy

14 · April 2020 ¦ international-dairy.com

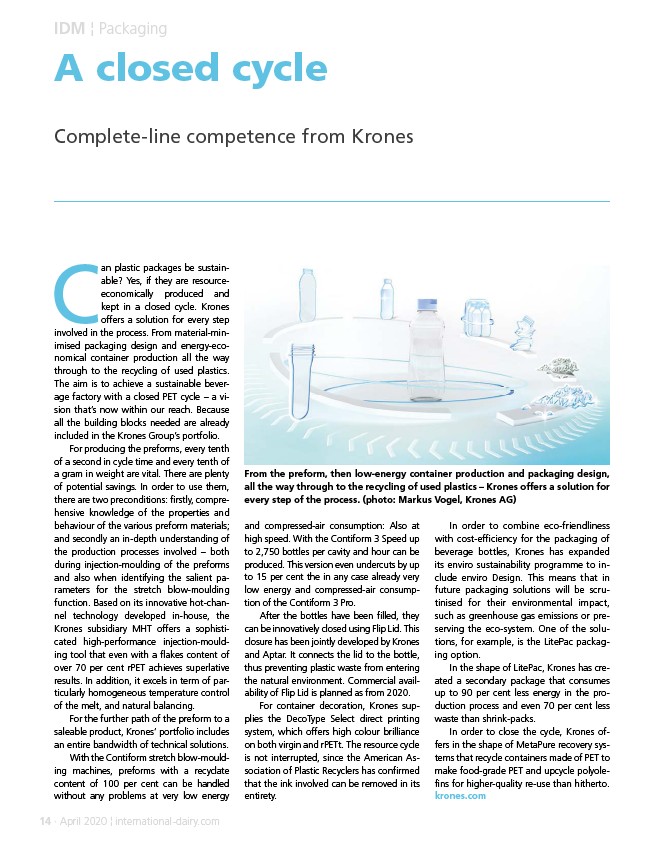

From the preform, then low-energy container production and packaging design,

all the way through to the recycling of used plastics – Krones offers a solution for

every step of the process. (photo: Markus Vogel, Krones AG)

and compressed-air consumption: Also at

high speed. With the Contiform 3 Speed up

to 2,750 bottles per cavity and hour can be

produced. This version even undercuts by up

to 15 per cent the in any case already very

low energy and compressed-air consumption

of the Contiform 3 Pro.

After the bottles have been filled, they

can be innovatively closed using Flip Lid. This

closure has been jointly developed by Krones

and Aptar. It connects the lid to the bottle,

thus preventing plastic waste from entering

the natural environment. Commercial availability

of Flip Lid is planned as from 2020.

For container decoration, Krones supplies

the DecoType Select direct printing

system, which offers high colour brilliance

on both virgin and rPETt. The resource cycle

is not interrupted, since the American Association

of Plastic Recyclers has confirmed

that the ink involved can be removed in its

entirety.

In order to combine eco-friendliness

with cost-efficiency for the packaging of

beverage bottles, Krones has expanded

its enviro sustainability programme to include

enviro Design. This means that in

future packaging solutions will be scrutinised

for their environmental impact,

such as greenhouse gas emissions or preserving

the eco-system. One of the solutions,

for example, is the LitePac packaging

option.

In the shape of LitePac, Krones has created

a secondary package that consumes

up to 90 per cent less energy in the production

process and even 70 per cent less

waste than shrink-packs.

In order to close the cycle, Krones offers

in the shape of MetaPure recovery systems

that recycle containers made of PET to

make food-grade PET and upcycle polyolefins

for higher-quality re-use than hitherto.

krones.com