IDM ¦ Cover Page

Maximum hygiene level

without using peroxide

Sophisticated sterilisation system for future-proof dairies

Respecting the environment, more ecology in food production,

wider range of natural products, avoiding chemical additives

– the consumers‘ list of requirements is extensive and could

be extended. Moreover trade has demanded extremely long

shelf lives for their products – and also for highly sensitive

products of the dairy and food industry – for a long time. Such long shelf

lives can only be achieved if the products are filled at a guaranteed high

hygiene level and if procedures are used which reliably sterilise the packing

materials (cup, bucket, lid and film) during the filling process.

GRUNWALD design engineers have been aware of these requirements

for a long time as the development of dosing and filling technology has

always been of great significance. Therefore a reliably high product safety

and the adherence to statutory hygiene regulations are one of the most

important issues at GRUNWALD for the development of new machines.

Ultraclean technology for higher demands

The mechanical engineering company from the Allgäu set new standards

with regard to hygiene with the certified and peroxide-free sterilisation

procedure developed 4 years ago. This ultraclean concept meets all requirements

for observing maximum hygiene levels in the production of

dairies and the food industry. Up-to-date machine technology guarantees

18 · April 2020 ¦ international-dairy.com

INTERNATIONAL

April 2020

Dosing Filling Packing

a reliably higher product safety and combines maximum possible

flexibility with maximum performance and reduction of running costs on

the basis of maximum hygiene standard at the same time. The hygiene

concept developed does not use peroxide and therefore respects above

all the health of the machine operators to a large extent.

The biggest advantage of this guaranteed reliable and certified

sterilisation system is not using any chemicals which means it is free

of peroxide and does not have any impacts on the environment and

personnel. In addition the issue with the overdosing of chemicals has

been solved! The pulsed light high-performance UV(C) sterilisation was

tested by several independent German institutes and they also confirmed

its effectiveness. They certified that this UV(C) sterilisation was

an ultra-modern and efficient alternative sterilisation procedure which

presents no health hazards and which gives reliable service without using

peroxide and guarantees maximum sterilisation rates.

Ultraclean sterilisation for cups and buckets

The pulsed light high-performance UV(C) sterilisation rate for cup filling

machines was well tried and tested over the past few years. It was developed

further and it can also be used on rotary-type and inline bucket fillers

for handling buckets up to 20 litres. A sterilisation rate of at least LOG4

is guaranteed for buckets from 1 to 10 litres. In addition this procedure

can be generally applied for all standard cups and lids used by the food

industry.

Peroxide-free machines

since 2019

The advantages predominate and Grunwald is convinced that basically

there is only one sterilisation system which can be thoroughly recommended:

the pulsed light high-performance UV(C) sterilisation. The number

of customers who made the decision for this ultramodern and efficient

sterilisation system which presents no health hazard and who have

used this successfully for a long time increases continuously. The reason

for this is not only due to the fact that Grunwald has manufactured their

cup and bucket filling machines exclusively with this peroxide-free hygiene

concept confidently since January 2019 but that both machine supplier

and customer consider the pulsed light high-performance UV(C) sterilisation

system to be THE trendsetting technology of the future.

PROCESSING INGREDIENTS PACKAGING IT LOGISTICS

www.international-dairy.com

Pettermandstraße 9

88239 Wangen im Allgäu/Germany

Phone +49 (0) 7522 9705-0

Fax +49 (0) 7522 9705-999

info@grunwald-wangen.de

www.grunwald-wangen.de

Titelseite IDM 04.2020

THE NEW ULTRA-CLEAN(UC) MACHINE GENERATION!

cup and bucket filling machine GRUNWALD-FOODLINER 20.000 UC

as fully integrated industry 4.0 solution in peroxide-free ultraclean (UC) design

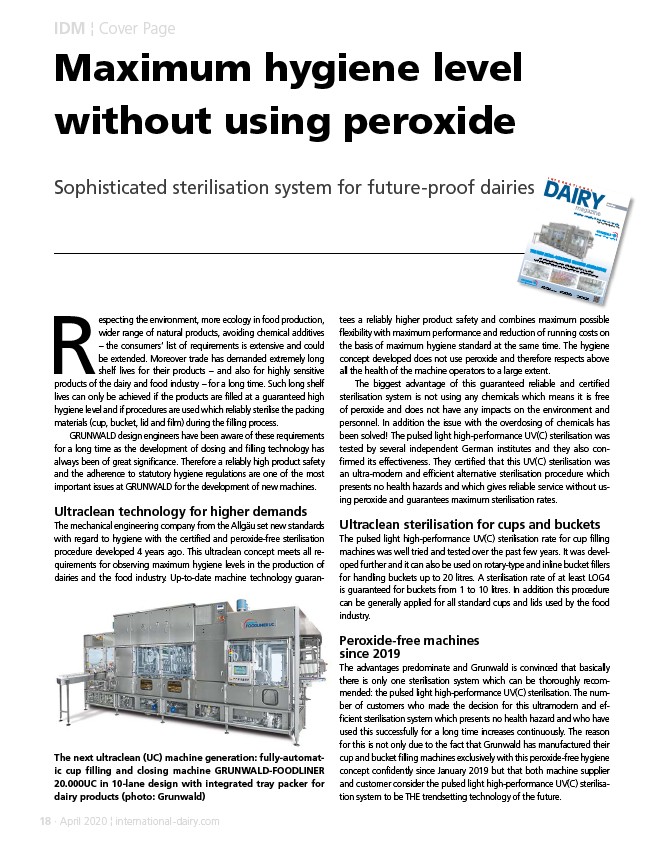

The next ultraclean (UC) machine generation: fully-automatic

cup filling and closing machine GRUNWALD-FOODLINER

20.000UC in 10-lane design with integrated tray packer for

dairy products (photo: Grunwald)